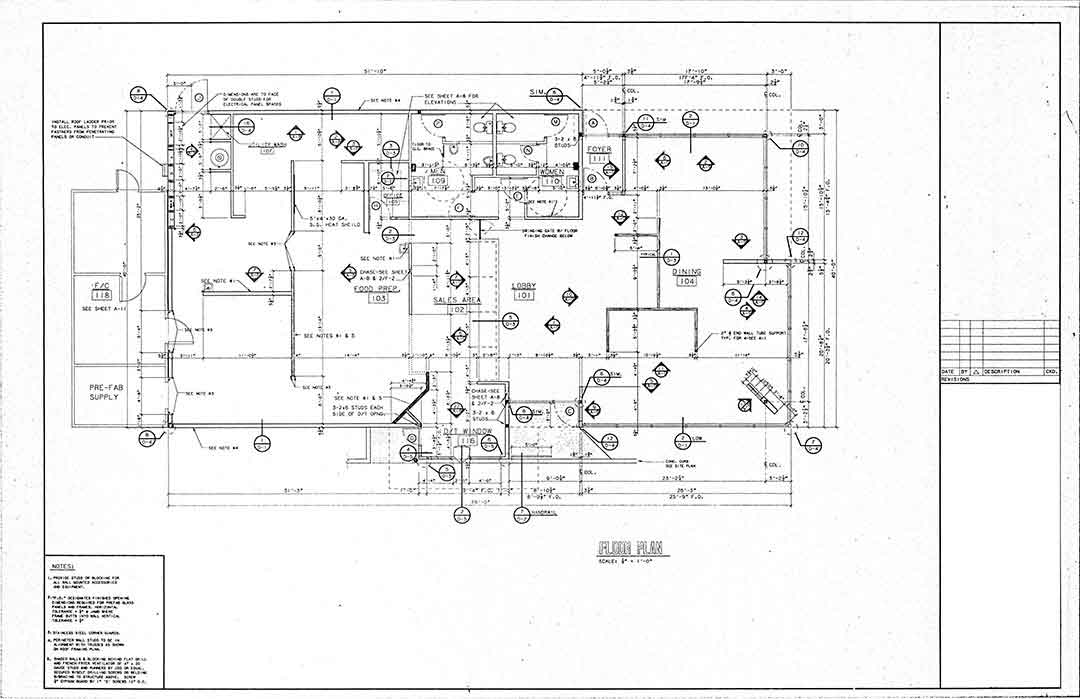

MEP (Mechanical, Electrical, and Plumbing) refers to the essential building systems responsible for heating, ventilation, air conditioning (HVAC), electrical wiring, lighting, and plumbing networks in a construction project.

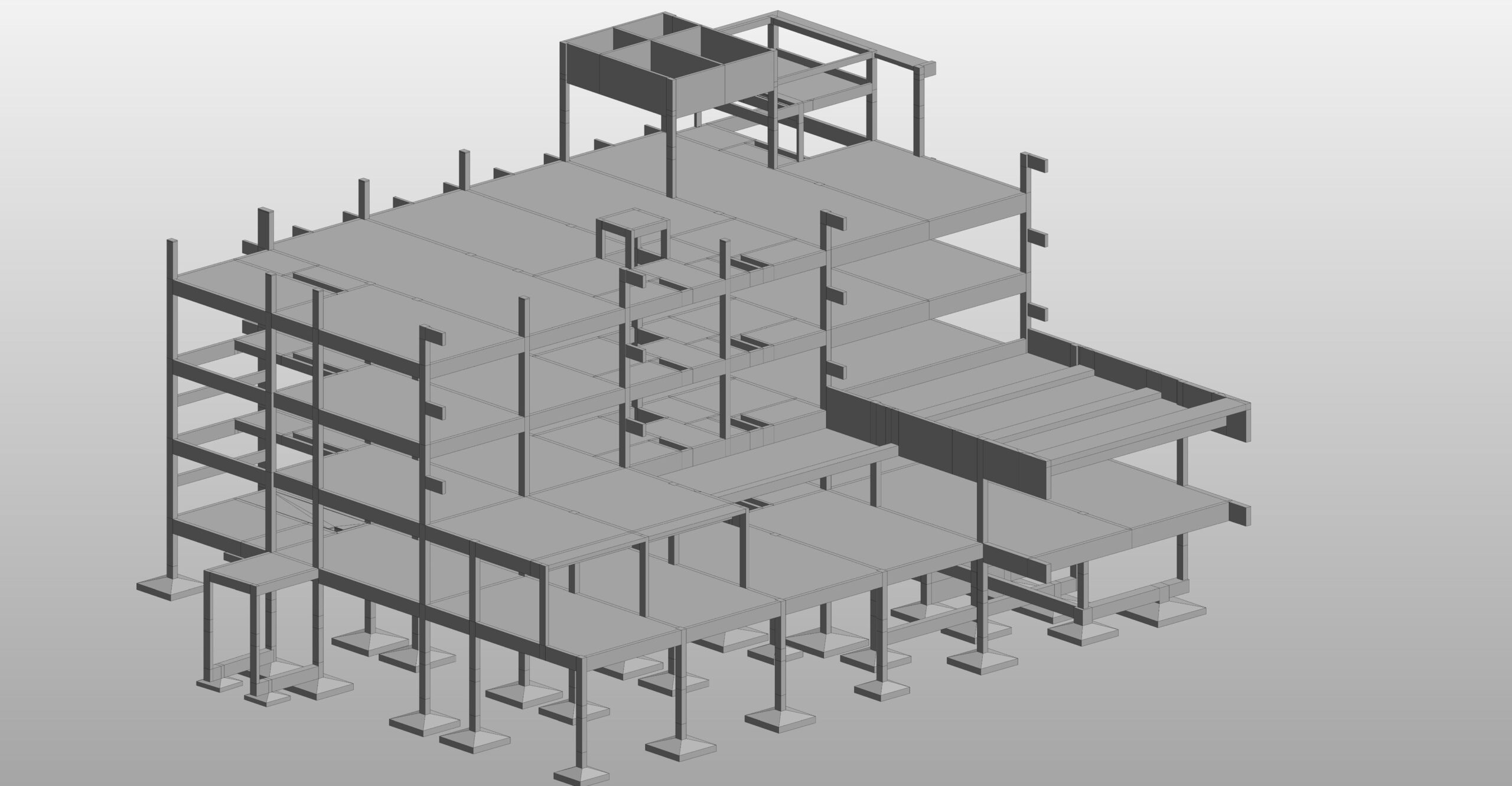

Using BIM (Building Information Modeling) for MEP design improves coordination, efficiency, and accuracy, ensuring all systems work together seamlessly within a building.

Key Components of MEP in BIM

1. Mechanical (HVAC Systems)

- Heating, ventilation, and air conditioning (HVAC) systems.

- Air ducts, chillers, cooling towers, and ventilation shafts.

- Ensures thermal comfort and air quality in the building.

2. Electrical Systems

- Power distribution, lighting, and emergency systems.

- Wiring, electrical panels, transformers, and fire alarms.

- Ensures energy efficiency and safety compliance.

3. Plumbing Systems

- Water supply, drainage, and sanitary systems.

- Fire suppression (sprinklers) and gas piping.

- Ensures efficient water management and waste disposal.

Benefits of BIM for MEP Design

✅ Clash Detection & Conflict Resolution

- Identifies clashes between MEP, structural, and architectural elements.

- Prevents costly rework and design modifications.

✅ Improved Collaboration

- MEP teams can work alongside architects and structural engineers.

- Cloud-based platforms like BIM 360, Trimble Connect, and Aconex enable real-time collaboration.

✅ Accurate Quantity Takeoff & Cost Estimation

- Extracts precise material quantities, reducing waste and cost overruns.

✅ Energy Efficiency & Sustainability

- BIM allows energy simulations to optimize HVAC and electrical systems.

- Helps meet LEED (Leadership in Energy and Environmental Design) certification requirements.

✅ Faster Installation & Maintenance

- Contractors use BIM models for prefabrication and on-site installation.

- Facility managers use the BIM model for maintenance and future renovations.